How to Build an Assembly Routing

In industry, a “process sheet” is a technical document. Depending on its objectives, it contains specific information for each step. There are several types of process sheets.

Simply put, the process sheet lists all the “development” phases of a part or a complex product up to storage. It records, step by step, the entire production evolution.

A process sheet is created with the purpose of defining all the steps to enable their analysis (costs, conditions, resources…) and feasibility (quality, investments…).

In this article, we focus only on creating an “assembly process sheet” and all the related requirements.

Different types of process sheets

The importance of writing an accurate process sheet is multiple. In summary, what different types of process sheets can be found in industry?

Assembly process sheet

The assembly process sheet is a document that describes the order and techniques of assembly as well as the joining components to use to connect all parts of the object.

https://www.alloprof.qc.ca/fr/eleves/bv/sciences/la-gamme-de-fabrication-s1452

A process sheet is linked to a bill of materials. Through the description (operating procedure), it lists the components and the quantity of components to be used at each step.

|

To take shape, the process sheet integrates important and diverse information that will influence choices, operating methods, strategies, resources… This information is particularly important for logistics, flow studies, workstation organization, investments, workforce…

Assembly/disassembly process sheet

An assembly process sheet (and a disassembly process sheet) are documents describing how machines should be assembled (and disassembled). The operation is broken down into tasks called “phases”. The document can be presented as:

- a table;

- a tree structure, also called “assembly/disassembly rake”;

- an exploded view of the machine.

https://fr.wikipedia.org/wiki/Gamme_de_montage_et_de_d%C3%A9montage

Manufacturing process sheet

The manufacturing process sheet is a document that describes, in detail, all the technical information required to manufacture a part or all parts of a technical object.

https://www.alloprof.qc.ca/fr/eleves/bv/sciences/la-gamme-de-fabrication-s1452

Sometimes called assembly process sheets, these are particular cases of manufacturing process sheets.

Machining process sheet

The machining process sheet is a sheet that gives the chronological order of the different machining operations of a part according to the available machining resources.

Why write an assembly process sheet?

The purpose of the assembly process sheet is to list all the steps required to assemble all components (as well as the joining components to use) to connect all parts of the object and obtain the final product. This document usually takes shape from the “birth” of the product on “paper”. Often, it is from this first “draft process sheet” that questions about the viability or feasibility of the project are decided. Then the process sheet will continuously evolve until its first completion, which is the start of production.

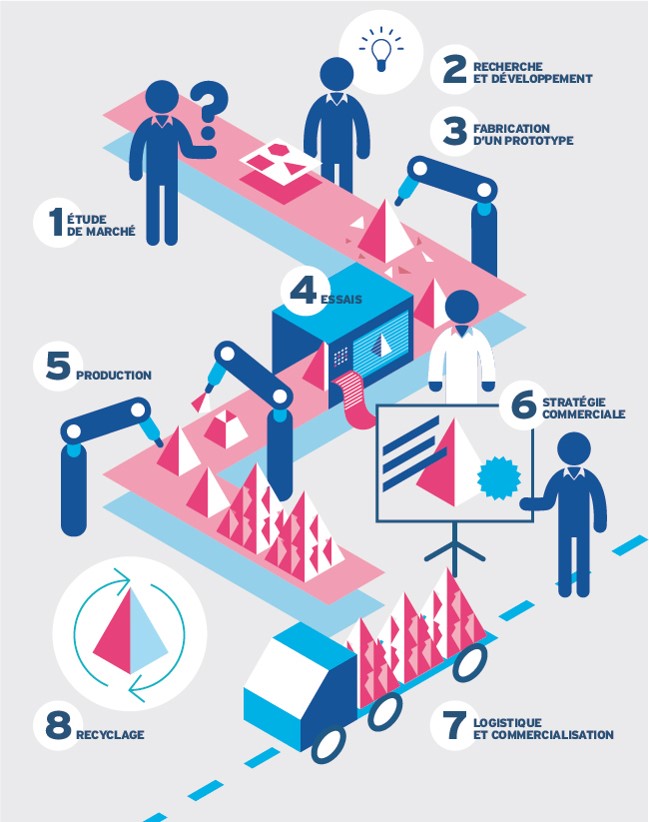

The process sheet through the product lifecycle:

|

- Market study: Process sheets can be created to help compare different product opportunities for the market.

- Research and Development: In R&D, the process sheet mainly tracks the first drafts of the product. At this stage, many external parameters are often ignored or “estimated”.

- Prototype manufacturing: From the “prototype phase”, the process sheet starts to take real shape and integrate external parameters like variety, assembly methods, difficulty, component sizes…

- Testing: The process sheet is industrialized to include times, Takt Time calculation, line balancing, workstation layout, product and process improvements…

- Production: The process sheet serves as a reference for organization, training, continuous improvement…

- Commercial strategy: The process sheet integrates parameters from the commercial strategy, which strongly influences the production strategy (stock, just-in-time, team work, subcontracting…). Many of these points are already considered in phase 2.

- Logistics, marketing, and recycling: The process sheet also includes all internal logistics related to the product and process (all internal flows, empty packaging returns…). This step is considered from phase 4.

Data influencing the assembly process sheet:

At the beginning of writing a process sheet, the list of steps mainly focuses on the product itself. Indeed, during the creation phase, engineers often “struggle” to solve assembly, quality, or appearance problems…

To evolve and meet the needs of many departments, the process sheet gradually incorporates a lot of input data from external services.

These external data come from different company functions:

| Data source | Types of input data |

|---|---|

| Sales Department | Production volumes, diversity, project longevity… |

| Logistics | Part volumes, storage, transport, handling resources… |

| General Management | Project location, investment budgets… |

| Production Management | Production policy, number of teams, overstock, just-in-time flows… |

| Quality | Quality grade, component inspection levels, production, finished product |

Expected outputs of an assembly process sheet:

Depending on the department, the process sheet provides specific information that allows them to organize and refine their specific studies.

| Departments | Expected information |

|---|---|

| Production | Machines, tooling, times, workforce, balancing, workstations… |

| Management | Investments, workforce, production costs… |

| HR | Number of operators, skills, training… |

| Logistics | List of components, packaging, handling at workstations, consumption volumes, diversity at stations, internal flows… |

| Project Management | Optimization of product, process, costs, deadlines, building space… |

Input Data for an Assembly Process

Based on the input information provided by the different departments, the results are analyzed to adjust and improve project costs and organization:

| Departments | Some of the information provided |

|---|---|

| Methods | List of components, workstations where the components will be used |

| Methods | List of resources (machines, tools, facilities…) |

| Methods | Estimation of times, balancing… |

| Production | Organization of buildings, lines, workstations… |

| Quality | Control means, procedures, costs… |

| Logistics | Storage of components and finished products, flows, handling equipment… |

| Finance | Costs of investments, production, and financing |

| HR | Training (costs, timelines, organization…) |

| General Management | Investments, production strategies… |

Who uses what in an assembly process

Once the process is completed, the different departments analyze the results. From this, the “continuous improvement machine” starts working to always reduce costs by optimizing all influencing factors:

- Design: highlights the “critical points” that need to be solved to obtain a high-performance product.

- Industrialization: forces the analysis, optimization, standardization… of the product

- Production: Allows the study of resources and organization of lines and workstations to meet the quantity to be produced (days, months, years), times, balancing…

- Logistics: list of components to order, definition of packaging for incoming components and final product, stock definition, flow study…

- Production management: planning, workshop organization…

- HR: if there are hires, training, personnel flows, skills, salaries…

- Finance: analyze costs, set optimization thresholds…

- General Management: if there are important decisions (investments, major reorganizations, production strategies such as relocating or outsourcing all or part of the production…)

Who writes an assembly process?

Writing a process is therefore not the work of a “novelist” but of a technician who has:

- Good knowledge of the product, process, quality, costs…

- A rich vocabulary and structured language.

The risk of each department (methods, logistics, production, training…) writing its own process will generate errors, misunderstandings, differences in information and updates, or even contradictions.

Generally, the task of writing the assembly process is assigned to the methods department. This department is at the crossroads of information. It is responsible for collecting the information, updating the process, and redistributing the information.

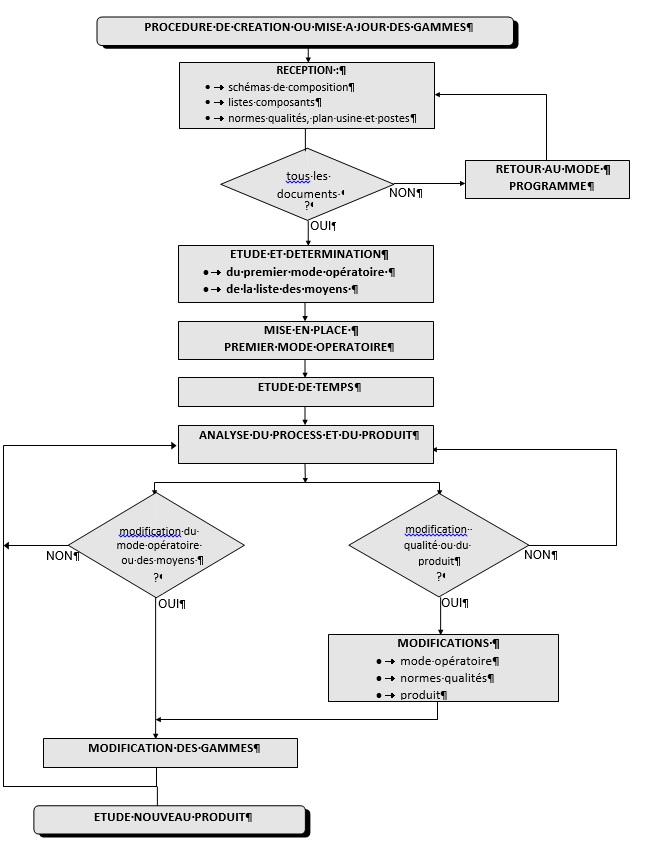

Who updates an assembly process?

Logically, the methods department. As mentioned earlier, it is at the crossroads of information.

Continuous improvements will appear. For example, the quality, ergonomics, or logistics departments may find it useful to add product or process updates impacting the procedure, workstation layout, resources…

These modifications are reflected and integrated into the official main process in order to take them into account and calculate the deviations that affect times, balancing, product and/or logistics flows…

Indeed, all changes, updates, improvements… have a cost that must be evaluated to decrease or increase the final manufacturing price.

Who validates an assembly process?

In most cases, it is the methods manager and/or production manager surrounded by other actors from different technical departments.

|

Once the process is approved, it is sent to the central or administrative departments.

What is the vocabulary of an assembly process?

In a company with multiple separate functions, the absence of a standard and precise technical vocabulary will generate “misunderstandings” that will affect the product, project organization… causing problems, delays, and inevitably cost overruns.

In a large company or group, training, professional backgrounds, and local vocabulary of staff are very heterogeneous. The vocabulary used by design, development, methods, logistics, administrative departments… often has “variants” to describe the same thing, whether it is:

- Components

- Machines and tools

- Operation titles

- Etc…

Moreover, within the same department or production site, reinforced by the risk of a “every man for himself” policy, the absence of an official technical vocabulary will create malfunctions (purchasing, logistics, production…) causing various problems and impacting the overall project performance to some extent.

It is therefore imperative to establish the technical vocabulary and ensure everyone “speaks the same language.” Whatever the size of the company, the vocabulary must be consistent and understood unambiguously by all.

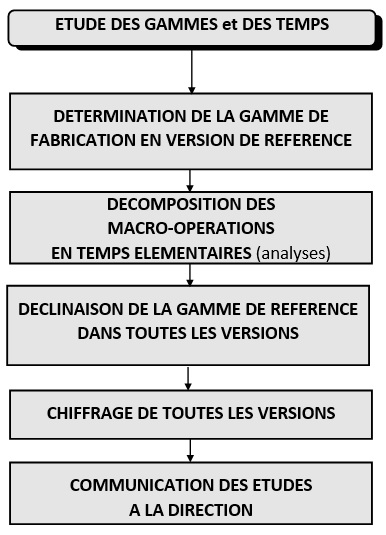

Creation of an Assembly Process

As previously mentioned, the process begins with the “first pencil stroke.” At this stage, much information is unknown. It is practically impossible (and unnecessary) to analyze all operations in detail. The process will be written in macro-operations obtained through:

- Product analogy

- Component analogy

- Specific data from technical catalogs (complete processes, complete functions, macro-operations)

- “Experience” or “educated guesses”.

Completely new steps will often be analyzed in more detail to avoid the risk of making too many errors in the final estimation.

Time study is one of the main objectives of writing a process. It is from this “key” information that many decisions are made. To obtain it, several steps must be followed.

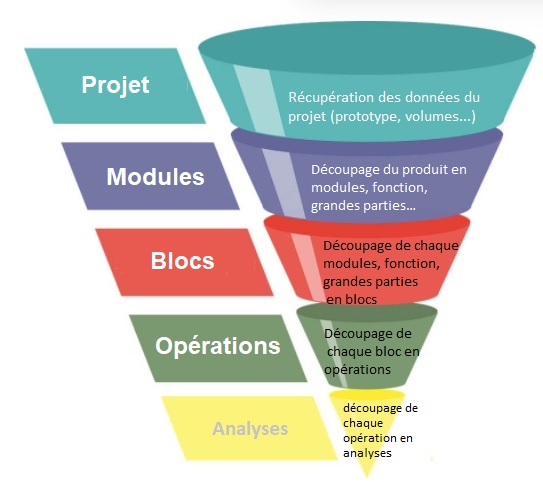

In the case of creating a new process from a “blank sheet” (with few possibilities for analogy), the approach will often be that of a “funnel.”

The funnel represents the different stages along the study process. There are 5 phases:

|

How to write an assembly process?

“A process is not a poem. It is a technical description.”

The text describing the content of a process should not vary according to the professional “imagination” of the reader. The information must be precise and unambiguous.

Indeed, this document will be used by many departments that do not all share the same technical culture and expectations. Moreover, everyone must easily find in the process the information they are looking for.

How to structure an assembly process?

Because gradually a process will become a mine of information. It must be organized and structured in its presentation.

Each line describing a single operation must itself be clear and precise, without unnecessary information or ambiguities.

Organization of data in an assembly process

The organization of information in the study document is important. We propose 3 parts:

1. General information of the process:

This information constitutes the input data. It is often presented across several documents with links allowing immediate recalculation of each according to the project’s evolution:

- Various information (product name, client, methods engineer name, study date…),

- Product variant diversity,

- Production volume for each variant,

- Takt Time,

- General data such as opening time, break time, information time… to know net working time,

- Study progress index,

- Etc…

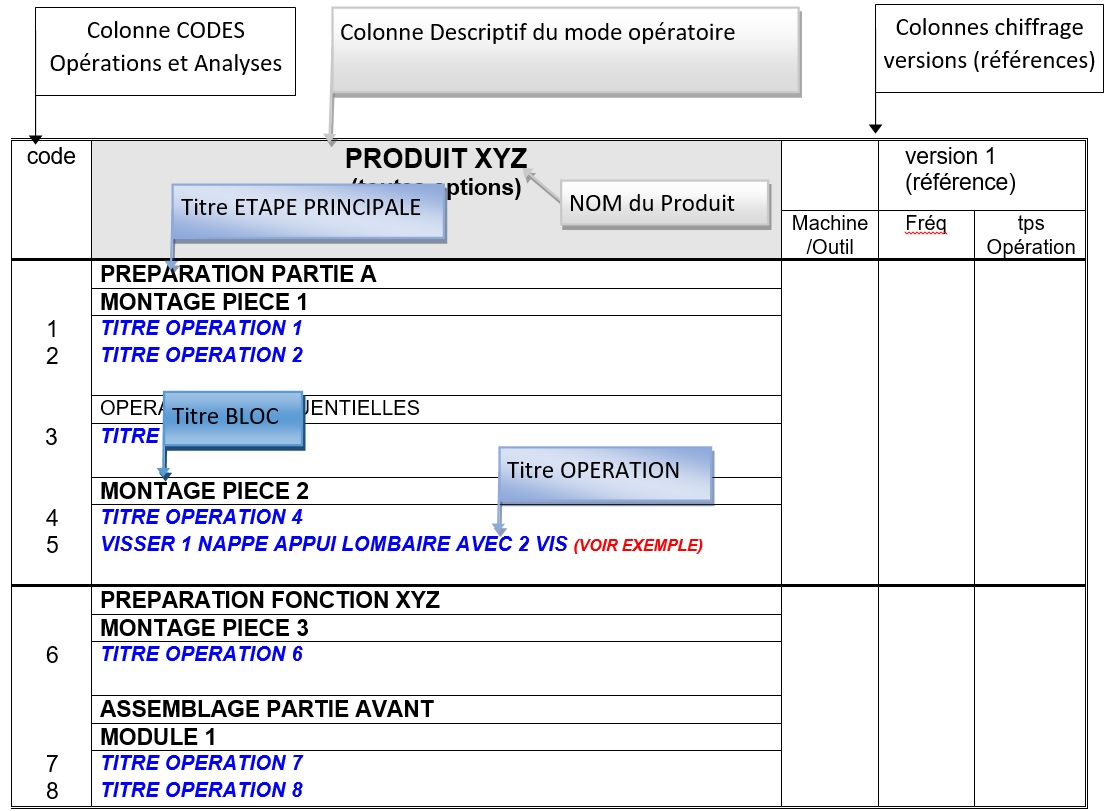

2. Description of the operating method:

This part is structured as an “accordion,” especially if the goal is to make the process evolvable and flexible.

- Main step titles (Example: file preparation, seat preparation, assembly, finishing, final control, evacuation…)

- Block titles (assembly of part 1, assembly of element 2, assembly of function X, product evacuation to stock…)

- Operations (screw 1 armrest onto frame, rivet 1 piece X onto element Z with 2 rivets…)

- Analyses (provide 2 rivets and keep in hand, provide 1 riveter…)

3. Study results:

This part is often presented across several documents using summary tables and charts:

- Time summary (Min – Average – Max)

- Number of line operators (Min – Average – Max)

- Number of operators per reference,

- Line balancing (Min – Average – Max)

- Balancing per reference, waits

- Variance analysis

- etc…

The presentation of the “operating method” section as an “accordion” can be inspired by the example below:

|

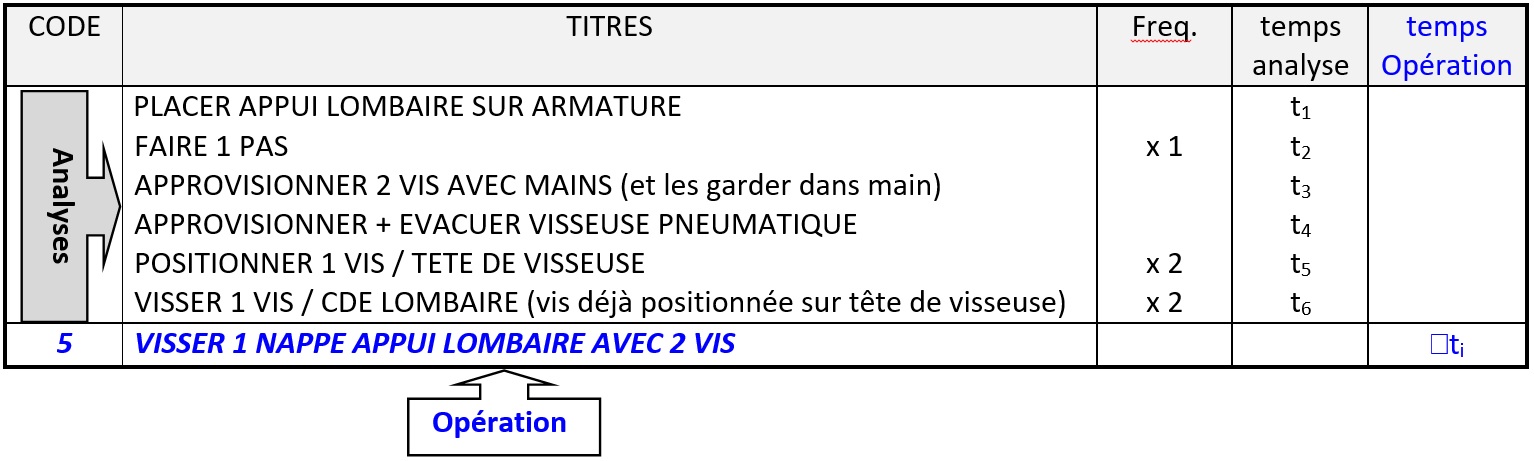

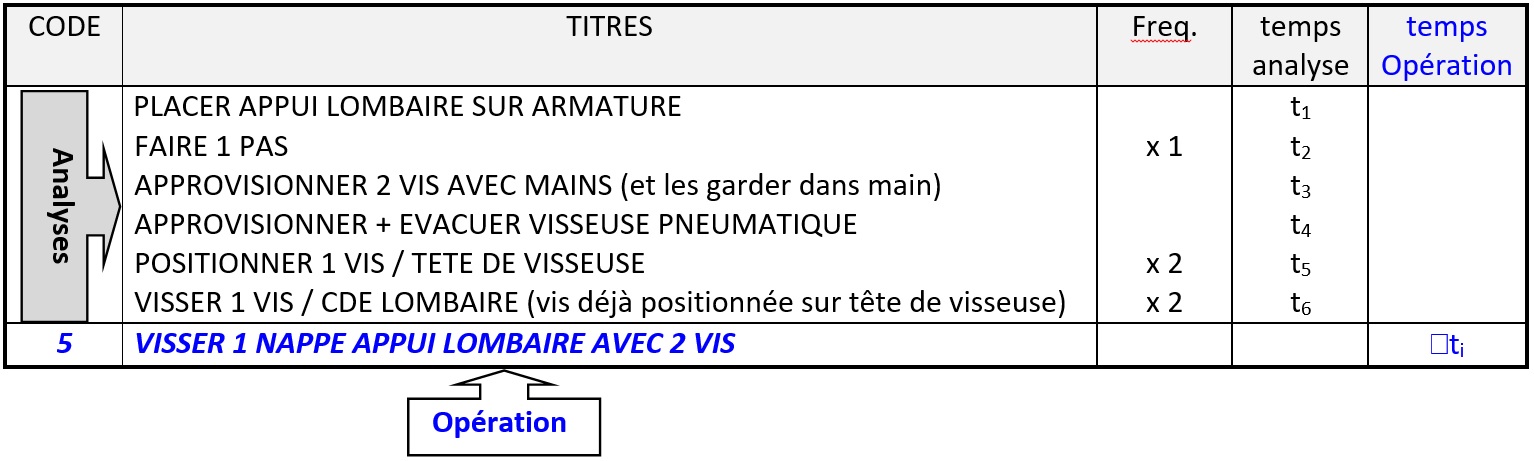

Below is the complete example of the structure of an operation, which will be very flexible to modify thanks to its analyses (micro-operations).

Operation: “SCREW 1 LUMBAR SUPPORT COVER WITH 2 SCREWS” which is divided into several micro-operations (analyses):

|

How to manage multiple variants in a process?

A product is often not unique for a project. This product will often be available in several more or less similar variants (references). However, among these product variants, many components (and therefore operations) are repeated.

Sometimes this involves:

- The same component across different variants

- A component similar to other variants but with an “option” added or removed

- Specific components for certain variants

- Different pick-up or drop-off distances depending on the variant (e.g., color diversity)

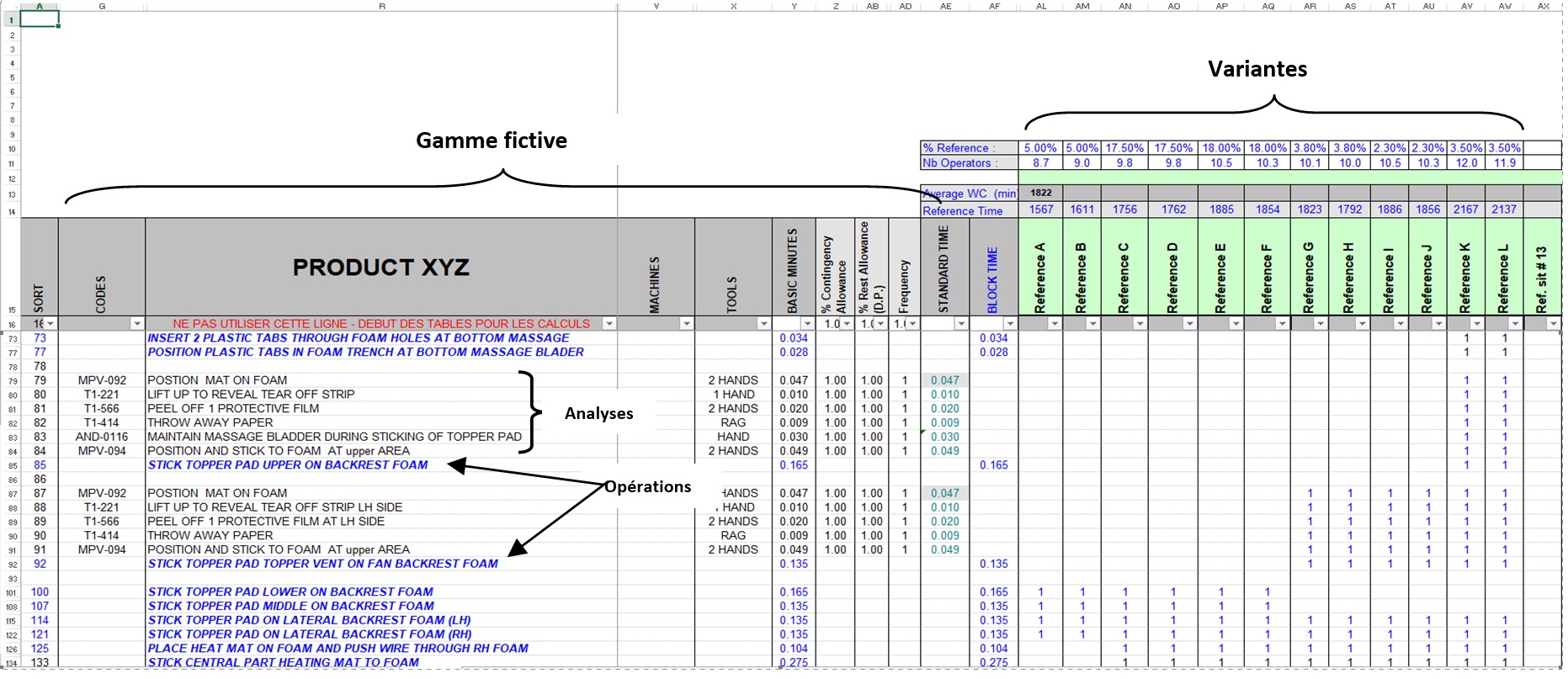

Fictitious process

If each variant is studied in separate documents, updates in case of modifications will be difficult and prone to errors, especially for the parts common to all references.

To avoid these “dangerous burdens,” it is preferable to:

- Create a single process, grouping all product variants. This process is called a “fictitious process” (see https://xn--prodple-x0a.com/lequilibrage-calcul-de-base/ )

- Detail all operations in analyses (micro-operations “Fixed” or “Variable”). Operation analyses can thus be adapted for each variant (reference) and configured directly within the process.

In the example: “SCREW 1 LUMBAR SUPPORT COVER WITH 2 SCREWS” from the previous section, it is possible to have:

- Different types of covers placed closer or further from the operator (number of steps?)

- A different number of screws to fix them (2, 3, 4… screws?)

To study the different operations induced by the variability of covers, it is enough to modify the frequency of the impacted analyses:

| Fixed analyses | Variable analyses |

|---|---|

| Place lumbar support on frame | Take 1 step |

| Provide 2 screws by hand (keep in hand) | Position 1 screw / Screwdriver head |

| Provide + Remove pneumatic screwdriver | Screw 1 screw (screw already positioned on screwdriver head) |

All the diversity of all variants in the fictitious process (process grouping all operations from all variants in assembly order) is then quickly studied. It is enough to vary the frequency of each analysis:

|

Once the operation is inserted into the process (with its analyses), it gives for example the result below:

|

Note: In Excel, creating this “accordion” presentation is easily done using the “Group/Ungroup” function.

The structure of titles

A process is mainly composed of operations, which themselves are composed of analyses.

The quality of the title writing is crucial. As mentioned earlier, the information must be precise, complete, and without interpretation.

| “Unfortunate” titles | “Good” titles |

|---|---|

| The operator takes the armrest and places it | Fit 1 armrest on DAR frame (supply included) |

| Take and place the armrest | Screw 1 airbag onto frame with 2 screws (manually) |

| Place armrest | Staple 1 rod through padding (1 hog-nose staple) |

General operation structure:

An operation is a set of actions called analyses (fixed and/or variable) that will allow the completion of a “small complete step” in product assembly.

The basic structure of a process operation can be as follows:

- Operation number

- Operation title

- Means to perform the operation (machine, tooling)

- Operation frequency

- Operation time (without and with possible multiplication coefficients)

- Comments

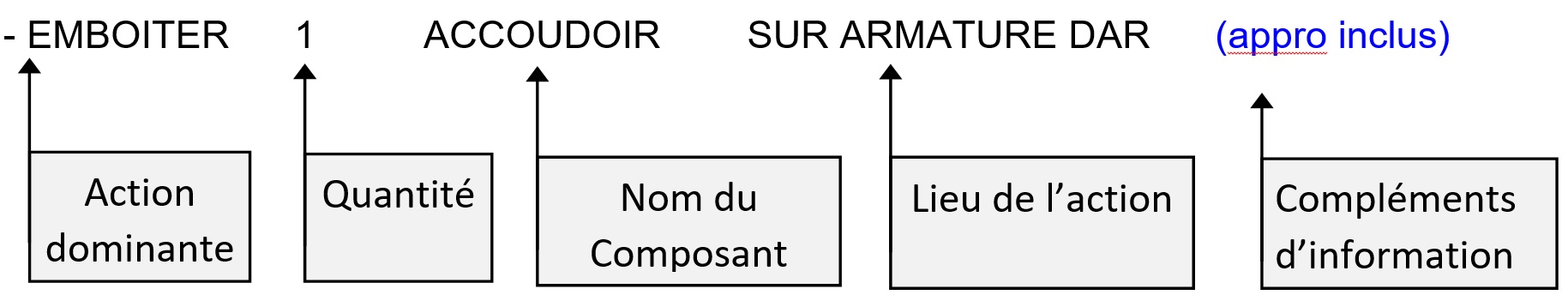

Operation title structure:

The structure of an operation title summarizes in one line the content of the procedure generated by the different analyses (micro-operations) it contains. It can be as follows:

|

General analysis structure:

An analysis is an action (fixed and/or variable) that contributes to the completion of an operation.

The structure of an analysis title summarizes in one line the content of the procedure generated by the gestures (manual, physical, technical…) it contains.

The basic structure of an analysis can be as follows:

- Analysis number

- Analysis title

- Means to perform the analysis (machine, tooling)

- Analysis frequency

- Analysis time (without and with possible multiplication coefficients)

- Comments

Analysis title structure

The structure of an analysis title summarizes in one line the content of the procedure generated by the different actions (gestures-movements) it contains.

The structure of the title is similar to that of an operation but often less “rich” because it usually targets a single, repetitive action.

| Examples of analysis titles |

|---|

| Provide and remove 1 mallet (at workstation) |

| Strike 1 part with 1 mallet blow (first blow) |

| Strike 1 part with 1 mallet blow (next blow) |

| Provide 3 gearbox nuts (and keep in hand) |

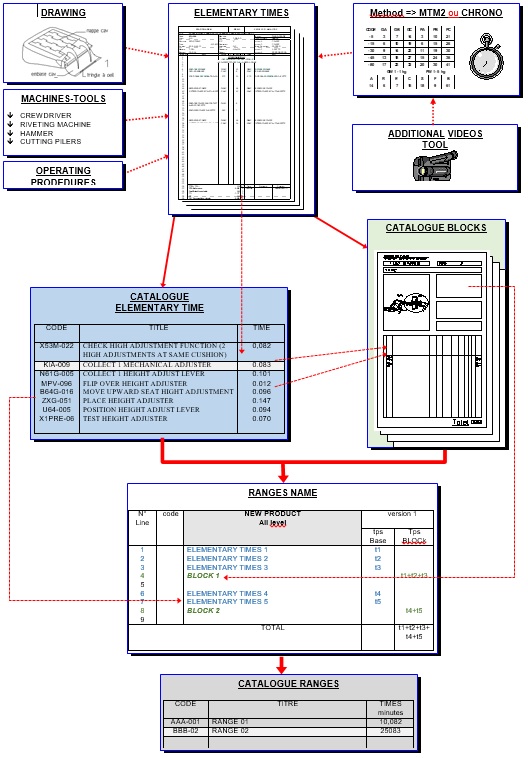

Tools for writing a process

In a company specialized in a type of product, more than 50% of the data required for a reliable study of a new product will be obtained by drawing from the know-how history:

Databases (catalogs).

The various databases, combined with the experience of engineers and technicians, will allow the company to respond to requests quickly and reliably.

The need to have a true, reliable library of know-how is vital. For this, it is necessary to have a well-structured database.

Below is an example illustrating this organization.

|

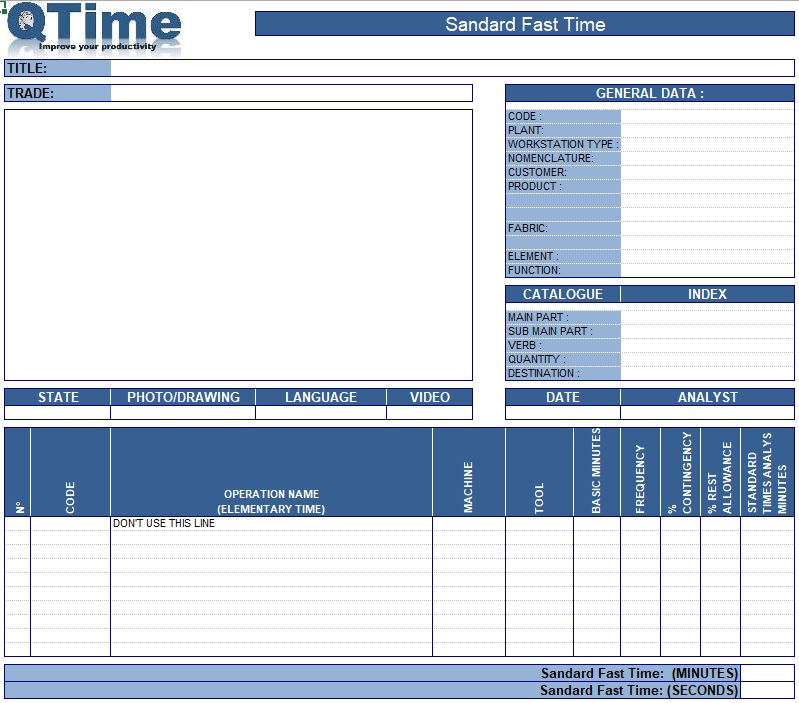

Operation Sheet

This document, sometimes called “Standard Operation Study Sheets,” provides a database of standard operations.

Definition of an OPERATION:

An operation is an action aimed at accomplishing a set of small actions to complete a specific step.

- starts: by taking the element from the container

- includes: all the micro-actions (analyses) necessary to place the element

- ends: with the element in place

This database will allow rapid costing of new projects. It is generally built from “standard analysis” sheets, making it flexible and adaptable to the diversity of variants.

|

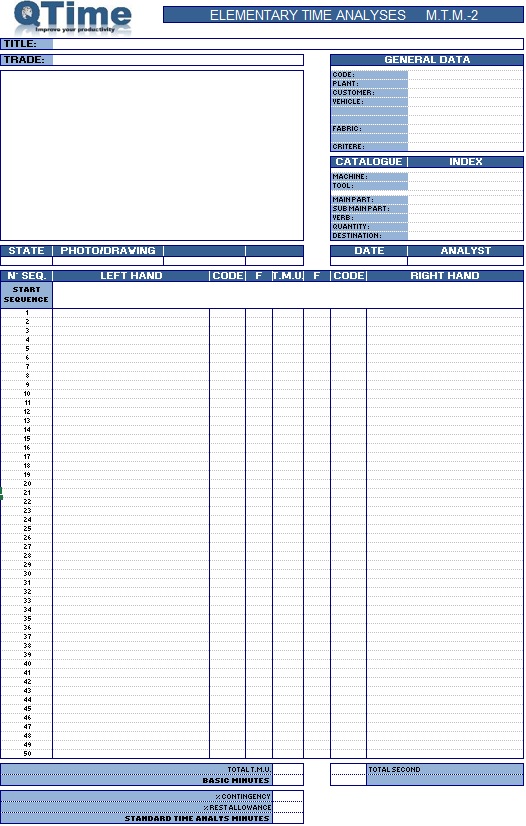

Analysis Sheet

This document, sometimes called a “Micro-operation,” provides a database of standard operations. This database is generally built from standard time methods such as: Timing, MTM1, MTM2…

Definition of an ANALYSIS:

An analysis is an isolated action (often repetitive) aimed at accomplishing a part of an operation. This action can be FIXED or VARIABLE within the operation of which it is part.

All these documents allow having a database of “standard micro-operations,” which enables rapid costing of specific operations and makes them flexible and adaptable to the diversity of product variants.

|

Operation and Analysis Catalogs

To quickly create a reliable process based on the company’s known experience, using an operations and analyses catalog is essential.

Operations catalog

Often, a new product contains many identical or slightly different operations. In this case, using the operations catalog will provide most of the required data.

Some operations will require adjustments (frequencies, removal or addition of analyses)

Analysis catalog

For new operations related to a very new product or component, using the analysis catalog is essential.

The new operations will be built from the available analyses (micro-operations). Missing analyses will either be created from standard time tables (MTM, MODAPS…).

Sometimes missing analyses will be estimated “from experience.” In any case, the risk of error from this approach is not significant. Indeed, even if the error is 50% on a 10-second analysis, the final impact is negligible compared to a 5% error on a 1-hour estimate.

To understand the purpose, organization, and operation of a catalog, see the articles:

– Creating a production time catalog

– Example of a time catalog

Studying processes with computers

The myth of the stopwatch board with the measurement sheet, using pencil and eraser, is still remembered by many.

Fortunately, today, electronics and computing have greatly improved this not-always-appreciated task.

Simple tools such as:

- A camera (or a good photo device)

- A PC

- A spreadsheet (Excel, for example)

are more than enough to meet the basic methods needs of a small or medium-sized company. Some large groups also use them and are very satisfied.

As shown in our examples in the previous paragraphs, we simply use a spreadsheet to manage all our data, such as:

- Description of procedures

- Times for all versions

- Calculation of Takt Time

- Workstation balancing

- Summary of results (times, workforce, ratios, charts…)

- Catalogs of analyses, operations, and processes

In conclusion

It was sufficient to develop a very flexible and scalable application in Microsoft Excel using VBA.

This simple tool allows managing all exchanges between databases for free and easily constructing extremely sophisticated assembly processes.

0 Comments