Manufacturing Time Calculation

Manufacturing time is only the result of the working method that has been chosen before it is calculated.

A boat can sail without a compass or maps. With good weather, calm waters, a favorable wind, the sun by day and the stars by night to find its way… everything is fine.

However, when conditions become difficult, unknown or uncertain… everything changes.

A company, without a time catalogue, can produce. With a strong market, comfortable margins, little or no competition… everything is fine.

But when business conditions change abruptly, competition appears, product variety increases, manufacturing lead times decrease… everything changes,

Then it becomes necessary to optimize, rationalize, organize… and to do so more and more quickly and accurately.

Why calculate manufacturing times?

If a company estimates its times “roughly”, “by approximation” or “by guesswork”… without data, without a time catalogue, without reliable history, without a culture of time accuracy…

it does not weakly manage its costs, its productivity, and may even fail to manage its long-term sustainability.

In a manufacturing company, times must be used not only as a measurement tool (quotations, organization, line and workstation balancing…), but also as an analysis and decision-support tool for organization, investments and overall efficiency. In fact, time is also:

- The pursuit of production efficiency

- The link with other productivity tools such as Lean, value analysis, continuous improvement…

- An excellent tool to control and compare solutions, equipment and human investments

- A way to anticipate in order to react faster and more accurately

- The construction of flexible process routings, both detailed and synthetic, reusable for future projects

- The creation of time catalogues, true databases of the company’s know-how

- A way to standardize tools, times, terminology, coefficients…

- Etc…

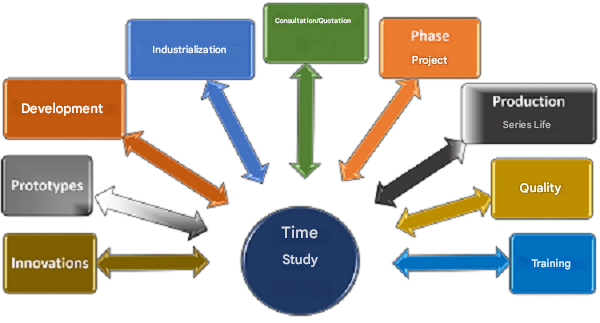

When and where should times be calculated in the company?

Times concern all areas of production. They must be studied as early as the product design phase.

Depending on the stage, time calculation tools vary according to the purpose and the level of accuracy required, for example:

|

When to calculate assembly times

- Project, prototype and development phase: using a solid time catalogue should cover at least 90% of the needs and make it possible to build a process. The remaining 10% will either be estimated using other tools or, at worst, evaluated “by guesswork”. At this stage, time studies are often carried out only to guide and support designers and prototypists in their choices.

- Industrialization, production, quality and training phase: the use of a Predetermined Motion Time System (PMTS) allows the methods technician to refine times by pushing the operating method into greater detail. This raises many questions and makes it possible to “correct course” very early.

- Start-up and mass production phase, Hoshin and Lean workshops: the use of time study by stopwatch is preferred. It validates predetermined time estimates, tracks deviations and enables immediate action plans.

In conclusion, all stages of a product’s life require time studies. Only the tools and the level of detail will vary. A routing and time management system makes it possible to track product/process evolutions and thus monitor cost variations.

Where to calculate assembly times

“It is at the back of the truck that the story of manufacturing times begins, and at the back of the truck that it ends.”

Indeed, the first operation a product “undergoes” is the unloading of its components (or raw materials), and it ends with the loading of finished products.

All internal flows can and must be analyzed, quantified and evaluated… because they consume time, labor and therefore costs.

Time studies highlight not only the necessity of an operation but also its duration and complexity. If an operation, workstation or product is difficult to analyze using a predetermined time method, it means that the product, the method, the operating mode or the organization… is not optimized.

|

Time and logistics

Time is therefore present at every stage of the production flow. It does not concern only the assembly area but all areas of the company.

Logistics (“supply chain”), upstream and downstream of the assembly line, is also part of the production flow. Time studies help improve and optimize the organization of this area, which is often considered indirect labor or “marginal”. Moreover, logistics choices impact other functions such as:

- The product (design, industrialization…)

- Logistics (packaging, types of internal or external transport, empty returns…)

- Production (flow and workstation organization, operating methods, tooling…)

- Production management (launch strategies, batch or piece-by-piece work…)

In summary;

Process analysis, work methods, resources and organization are part of productivity improvement efforts.

Everywhere, simplification of work, ergonomics, reduction of strain and optimization must be measured. But time is only the means of quantification; it must also be put into practice.

Which production time calculation method should be chosen?

Depending on the company’s sector, the product, volumes… the tools used to calculate times differ.

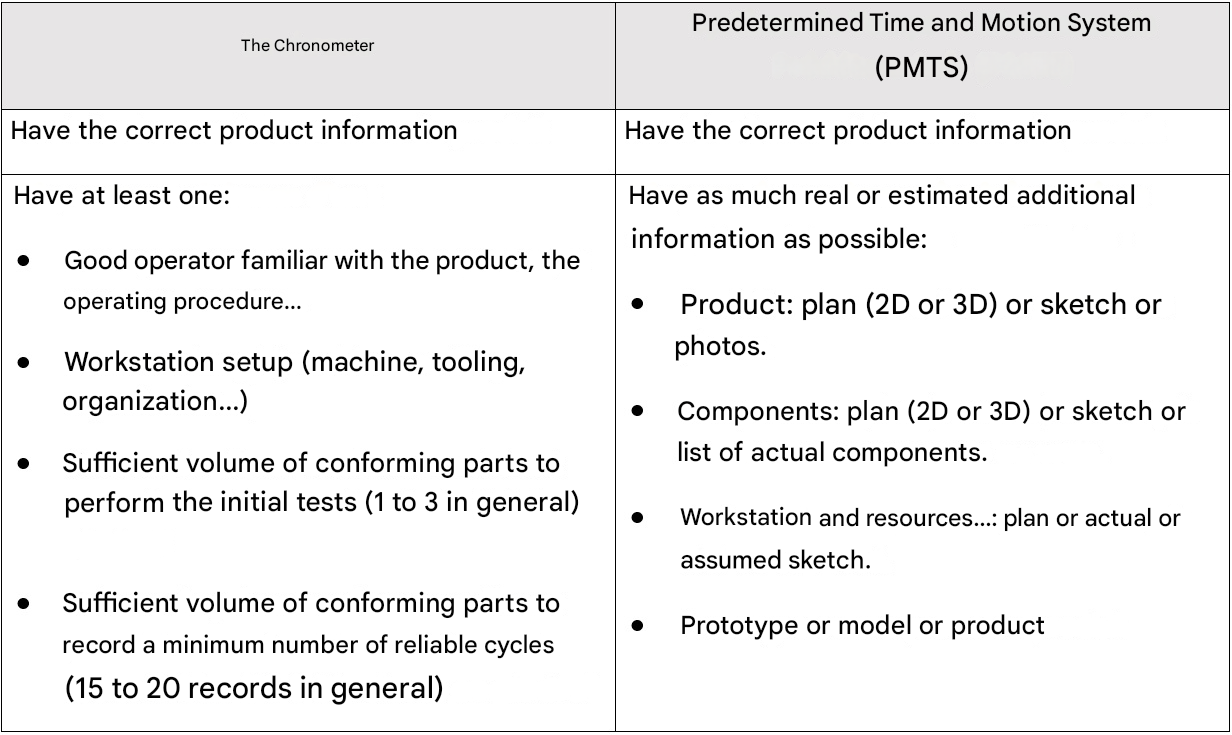

Moreover, some tools cannot be used at certain project stages. For example, during the study phase, stopwatch time study is not possible because there are no parts or workstations yet.

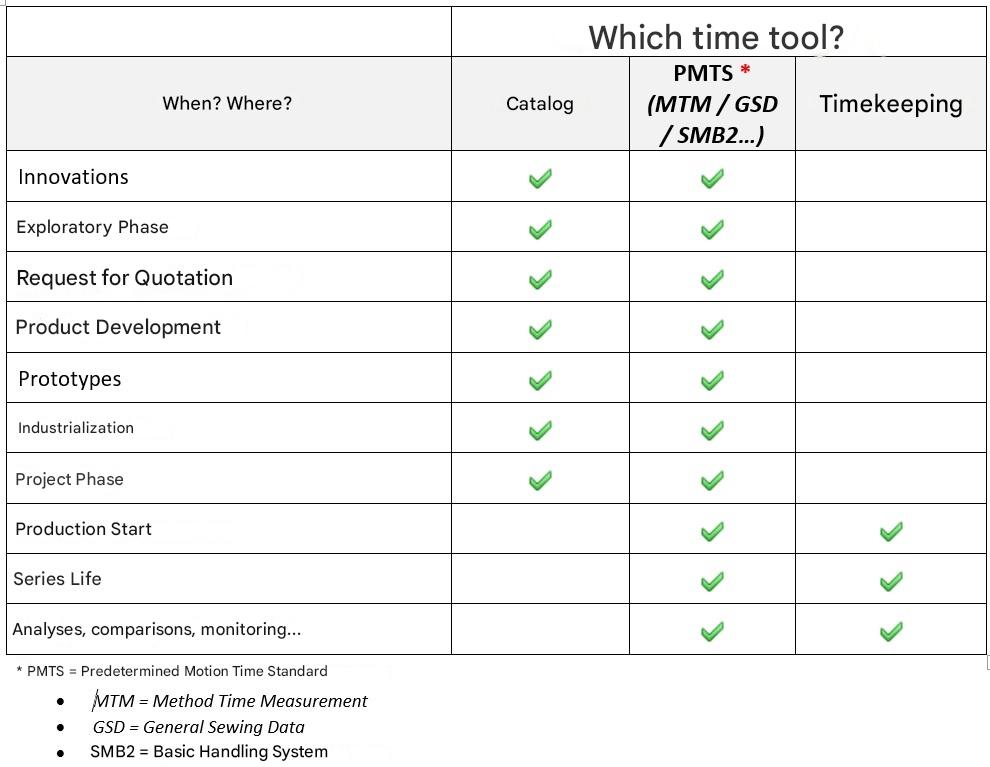

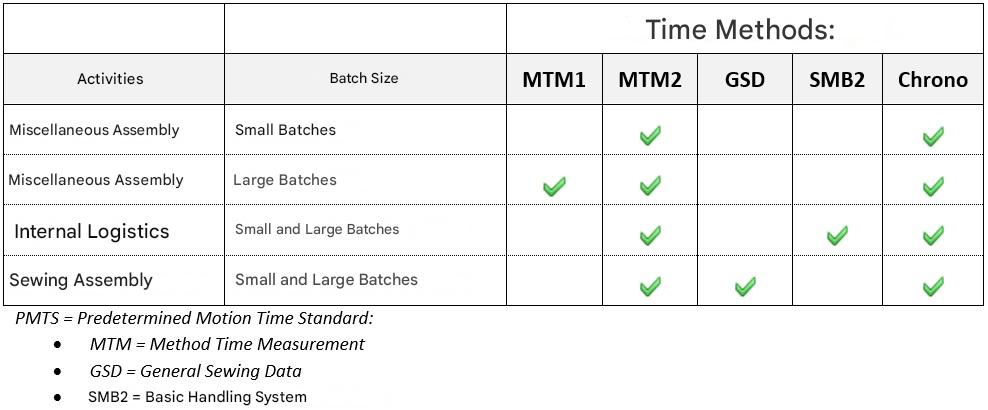

In the tables below, we summarize the main tools we use according to project phases and study types, available information, project stakes (volume, product…), and study lead time (urgent or not)…

1 – According to project phases:

|

2 – According to study types (projects):

|

Advantages / disadvantages of different time calculation tools

Depending on the company’s sector, product and volumes… the tools used to calculate times vary. Overall, three main tools stand out:

- The time catalogue

- Stopwatch time study

- Predetermined time systems (referred to as PMTS)

which is enriched using two types of time calculation methods:

As in many fields, time measurement has its “hardliners”. There are:

- The “all stopwatch” supporters

- The “anti-stopwatch” supporters.

For these newcomers (or cases of misunderstanding) who advocate stopwatch-only approaches, the main arguments are: stopwatch studies are fast and “true” because they reflect reality through direct measurement on the shop floor.

In reality, there is no universal method. Depending on the product, volumes, organization… and above all the stage in the product life cycle (prototype, mass production…), times will be calculated using different “tools”.

The choice of the “tool” is therefore driven by the need:

- Cost study, prototype, mass production, analysis…

- Batch size (small, medium, large)

- Calculation lead time

- Required accuracy (estimation, production organization, training…)

- Etc…

Stopwatch time study measures what actually happens, not always what one would like to see.

All micro-variations, operator dexterity and performance rating judgments affect the result. Figures often need to be “processed” to extract a coherent value.

PMTS (MTM, GSD…) “quantifies” what is intended, even if it is not yet visible at the time of calculation. During prototype, pre-series or production start-up phases, PMTS times may appear impossible to achieve. These are often referred to as “fictional times”. However, by staying the course, correcting disturbances, improving operating methods and adapting organization… the target will gradually be reached, or even exceeded.

From our perspective, neither of the two is faster or more accurate than the other.

Both systems have their own rules of use and present advantages and disadvantages in learning, application and evolution.

In terms of speed, stopwatch studies and PMTS are roughly equivalent (for equal accuracy):

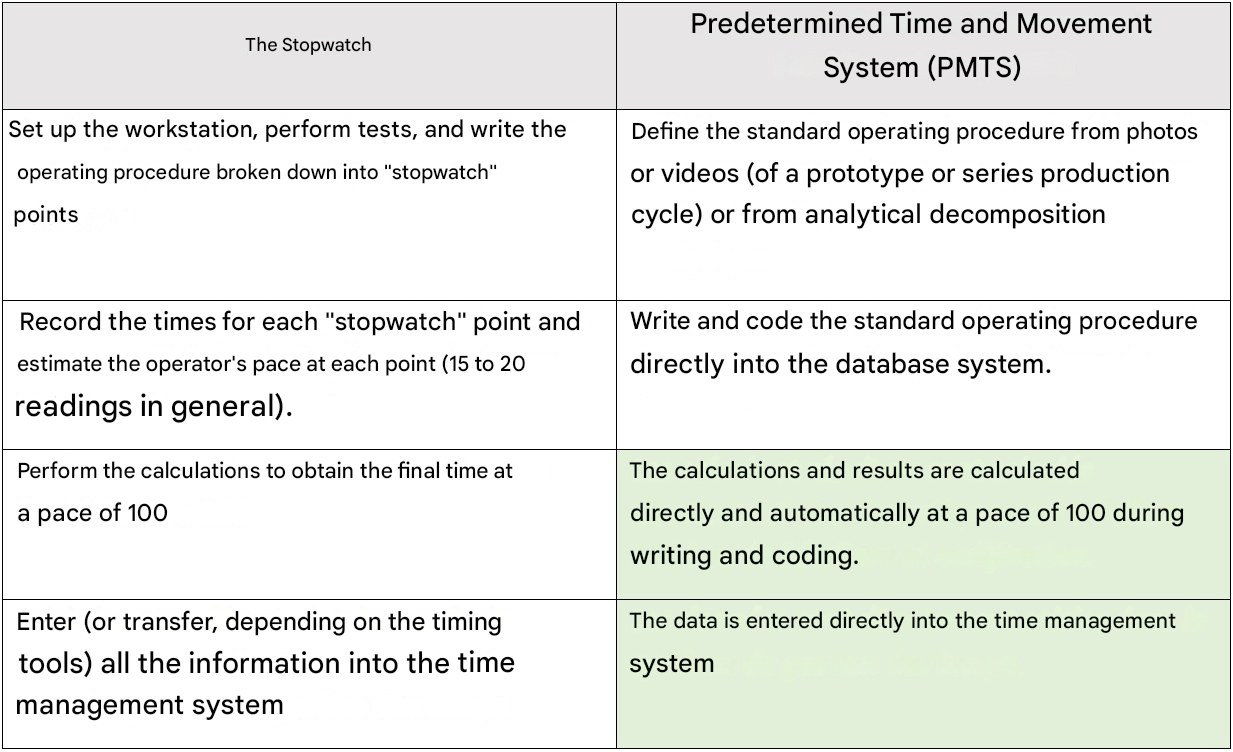

Study preparation:

|

Time measurement:

|

Strengths:

| Stopwatch time study | Predetermined times |

|---|---|

| • Universal tool, easily and quickly adaptable to any type of product and organization. | • Essential for development support and process tuning. |

| • Excellent for quick measurement, estimation, training follow-up, problem detection, Hoshin and Lean workshops. | • Enables simulation and comparison of solutions to guide decisions during studies and mass production. |

| • Means of validating PMTS times during production start-up and ramp-up phases. | • Detailed definition of operating methods and preparation of training, especially for long production runs. |

| • Overall, an excellent shop-floor tool. | • Definition of production policy, number of teams, stock organization. | • Enables standardized management of company times through a transparent, cross-functional and stable system. |

Weak points:

| Stopwatch time study | Predetermined times |

|---|---|

| • No time without parts, workstations or operators. | • Not the ideal tool for very rapid changes on production lines. |

| • Does not allow preparation (simulation before the intended change) of a Hoshin or Lean workshop. | • Little or no interest for operator training follow-up. |

| • Times are not flexible or fine-grained enough for breaking down operations into very short durations… (1 second is very long in short, highly repetitive cycles). | • Not convenient for shop-floor monitoring of production line ramp-up. |

| • Stopwatch times are often questioned because the accuracy of the information can be easily challenged. | • Not practical during Lean or Hoshin implementation. | • Mastery of performance rating judgment is essential for all official time estimations. |

0 Comments